We produce and customize according to individual wishes and orders. The final price depends on the characteristics chosen.

Select

Original

Rustic

Rustic Loft

Chevron 30°

Chevron 45°

Herringbone 90°

Wooden floors from oak covered with multilayer finish (up to 6 layers). Two layers of natural drying SAICOS (Germany) hardwax oil applied.

MASTRI TOSCANI collection created in collaboration with Italian designer Enrico Piselli.

Available prefinish – only distressed.

Wood is a natural product, a unique creation of nature, so the color may vary slightly.

We produce and customize according to individual wishes and orders. The final price depends on the characteristics chosen.

Top quality oak floorboards. They are characterized by low variations in colour, only single, small sound (live) knots are approved in the process of manufacturing. Such floorboards create an image of luxury, they are impressive both in natural oak colours as well as when they are covered with a multi-layer (natural oil) finish.

Oak floorboards are characterized by a small, moderate knots, natural colour differences of wood.

The limited number of small and larger, healthy and filled knots emphasizes the naturalness of the oak wood. No core boards nor sapwood permitted. These oak floorboards are both expressive and reserved, so they go well with a variety of interior solutions.

Oak floorboards are characterized by knots, more colour variations, natural micro-cracks. Such boards have a contrasted wood pattern with sound (live) knots and larger filled knots that are not limited, there may also be some core boards. The knots emphasizes the liveliness of the wood, and the variety of colours reveals the true beauty of the wood.

Oak floorboards are characterized by bigger number of various knots, natural micro-cracks, lush oak wood patterns. The number of sound knots is not limited, larger filled knots also provided. Core boards and sound sapwood provided. These floorboards are extremely expressive, provide a feeling of naturalness and nature even in emphatically industrial loft interiors.

Your opinion is important to us! We always strive to improve in our field, which is why we are truly grateful for your feedback, notes and comments.

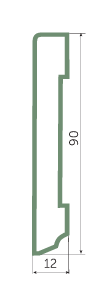

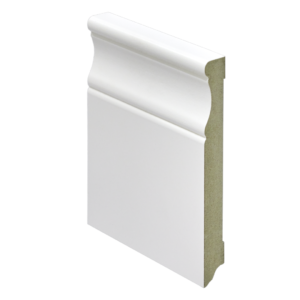

Oak skirting boards add a perfect finishing touch to your floor, making a seamless connection between the walls and the wooden floor.

– Top layer: natural oak plywood.

– Base: finger-jointed solid oakwood.

You can also choose MDF skirting boards (with a MDF base):

– Top layer: impregnated paper. Possibility to use any colour from the RAL palette.

– MDF base.

We recommend using STAUF adhesives – choosing right parquet adhesive is one of the most important points while installing a wooden floor. The right adhesive will increase the service life and performance of your floor. You can appreciate all the benefits of your wooden floor only if you use specialist and reliable adhesive.

To achieve best results, it is very important that you choose adhesive based on the type of flooring you plan to install: whether it is a two-layer, a three-layer or a solid wood floor.

We do represent STAUF, a leading company in the German adhesives industry boasting over 175 years of experience in the production of adhesives. These adhesives are suitable for underfloor heating. The most common types of adhesives used in installing floors are polymer adhesives, polyurethane adhesives and solvent-based adhesives that do not contain any water. When using these adhesives, wooden flooring can be glued directly onto the concrete sub-floor.

We recommend using SAICOS oils. In most European countries, finishing floors using oil is more usual than using lacquer as a finish. In Lithuania, lacquered finish is still a predominant trend, however, each year oiled floors are becoming increasingly popular.

Oiled flooring and its benefits

– Floor oil is usually chosen to keep the wood as natural-looking as possible: oiled floors look as though they are not coated at all. This is because oil is absorbed into the top layer of the wood once applied, whereas lacquer forms a coat on top of the surface of the wood which is more or less glossy.

– Easy repair of specific surface areas. In case of lacquered surfaces, it is difficult to repair a specific area of the floor because there will be a visible line between the old and the new lacquer finish, thus you have to sand the entire floor and re-apply lacquer all over the entire surface. In oiled flooring, there is no need to sand the entire floor. It is enough to sand the repair area and impregnate it with oil. The line between the old and the new oil finish will not be visible.

Natural

– Oil is made from natural plant materials – plant waxes and oils such as carnauba wax, candelilla wax, soybean oil, sunflower seed oil and thistle oil, and paraffin waxes. Oil does not contain biocides or preservatives. Oil is suited for all types of wooden flooring.

– Oil naturally protects the wood, allows it to breath and controls moisture.

Practical

– Oil is suited for treating all types of wooden surfaces including hardwood, multi-layer and plywood floors, cork flooring as well as intensively used surfaces, such as desks and table tops.

– Oil is a recommended method for finishing children’s toys.

– Ideal for the surfaces of the indoor areas with elevated moisture levels such as bathrooms and kitchens.

– Oiled floors are easy to clean, to maintain and to repair.

People often struggle to decide between lacquered, oiled or wax parquet finishes. When selecting a parquet lacquer, it is very important to choose the one that is resistant to wear (scratching and scuffing) and elastic (remains crack-free even when the wood is deforming). Another important quality of lacquer which is increasingly taken into account by customers is how eco-friendly it is.

If the parquet is poorly sanded and improperly coated with lacquer, all the flaws and irregularities will become visible. This stage of installation requires the utmost skill and attention to detail. Our experience has shown that customers who purchase high-quality flooring but use poor quality or improper adhesive, are disappointed with the final results.

We offer high-quality, eco-friendly water-based parquet lacquers:

Proper floor base preparation is one of the most important factors for a successful installation of a wooden floor or a parquet.

You can start floor base installation only after making sure the humidity levels of the room and the concrete slab are appropriate. The relative humidity of the indoor area should preferably be 40 to 60 percent and the indoor temperature should be 15 to 25° C.

Wooden floor can be installed on the following bases:

– A concrete base with a moisture content of no more than 3%.

– Subfloors, panels or plywood with a moisture content of no more than 12%.

If a wooden floor is installed in a room with moisture sources (a basement, a swimming pool, etc.), waterproofing is required in order to prevent moisture from entering the wood.

A concrete base must be level, firm and even. A parquet is glued to the concrete base using a special adhesive which does not contain any water (SMP-930, WFR-T).

When installing a wooden floor over underfloor heating, the underfloor heating should be switched off 24 hours before the start of the installation.

Our experienced and reliable specialists will come to your home anywhere in Lithuania to take custom measurements and will professionally install the floor, the door or the staircase of your dreams. Precision and superior craftsmanship is their top priority. We also provide warranty for our products.

More about installationWe will contact you within 1 working day for an individual offer.

We will contact you within 1 working day for an individual offer.

We will contact you within 1 working day for an individual offer.

Contact us